Description

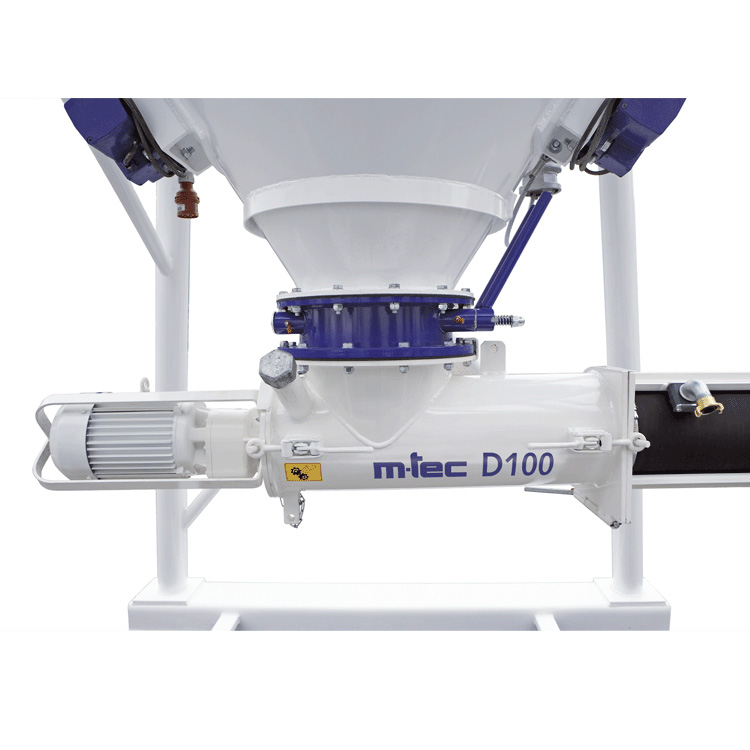

D100-II Continuous Mixer Fitted with a powerful 5.5 kW motor it mixes even heavy products with ease. The direct mounting on the silo creates a compact unit that speeds up work on the building site whatever the weather.

As is typical of all m-tec systems, the D100 has easy and quick to use connector systems that enable important elements, such as the mixing chamber or mixer motor, to be replaced in just a few seconds.

The m-tec S100 control panel is the control unit for mixer D100. It can cope with every situation and a number of different versions are available in line with the performance of the continuous mixer. Starting from a hand-operated, economical basic model and ranging to a fully automatic version with remote control, timer and special control, the m-tec S100 control panels meet every challenge a modern building site can produce.

Easy Use

Well-organized controls, easy dismantling and maintenance combine to make the D100 very easy to handle.

Easy Life

Tried-and-tested solid steel components ensure a long service life and easy maintenance.

D100-II facts

Areas of use and applications. All dry mortars, such as:

- Bricklaying mortar

- Floor screed

- Cement plasters

- Finishing plasters

- Screeds

- Fine concrete

Scope of delivery

Continuous mixer incl. mixer motor, transport screw and mixing shaft. The associated control panel S100 is ordered separately.

For details please contact your local sales representative or dealer.

Recommended accessories

- Control panel S100

- Rain-proof cap

- Mixing shafts

- Transport screw