Description

T115 Vessel Type Gunite Machine has a built-in in a rigid frame with reliable operation, simple handling and easy transport by crane or forklift to the place of operation make the UELZENER T115 most suitable for the fast repair in the Refractory applications (hot-repair) of electric furnaces, converters and runners. In addition this machine is ideally suited for production line civil sprayed concrete applications.

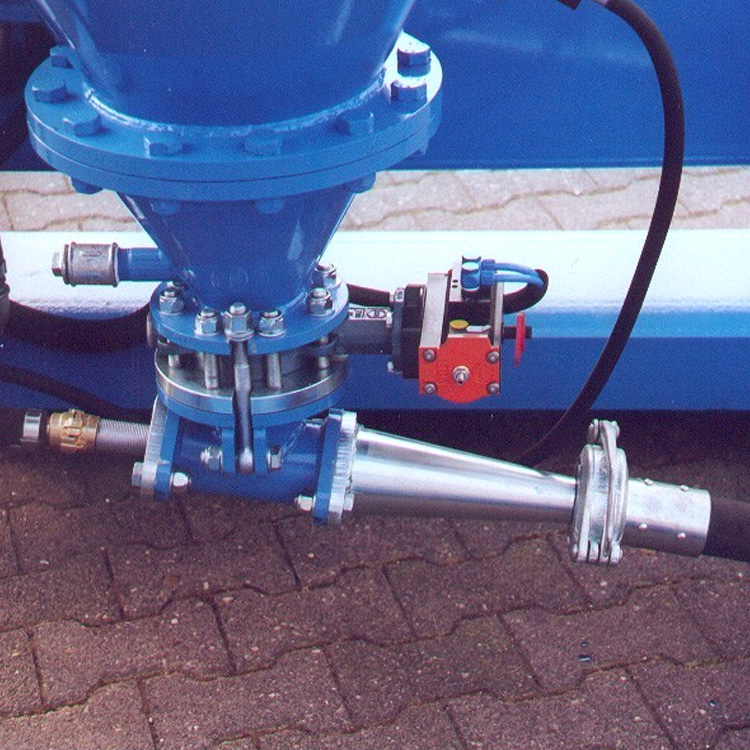

The wear at the UELZENER T115 is very low, as the machine works without any rotating parts within the material. The steady feeding of the dry material into the hose line is effected only by a defined relation between the chamber pressure and conveying pressure. This is specifically adjustable to the requirements of the material used. Because of the steady feed of material and optimal air supply the constant conveyance of the material is achieved and a surging of material is avoided.

The operation of the UELZENER T115 is fully automatic. All important functions such as adjustable pre blowing time, opening and closing of the material discharge flap, pressurising and de-aeration of the chamber and adjustable time for emptying the conveying line are automatically controlled by the free programmable PLC control. Any wrong operation is herewith avoided. A further charging of the pressure chamber is only possible once the chamber is fully relieved from pressure. A level probe in the chamber prevents over filling of the vessel. An electric remote control can be installed to operate the start / stop of the machine and also the filling of the Vessel with material so that the Sprayed Concrete / Refractory application can be completely controlled by only one operator.

Options

- Conveying hoses of different length and nominal width

- Shot cast lances of different length (2 – 10m)

- Lance support caddy, manually or electrically, for lances of more than 5 m length

- Weighing device for controlling the consumption and content of the pressure chamber

- Feeding funnel with cutter for Big-Bag feeding and connection for dust absorbing

- Dust absorbing system for installation in the machine frame together with the feeding funnel

- Simple rack for Big-Bag

- High pressure water pump for optimum moistening of the material